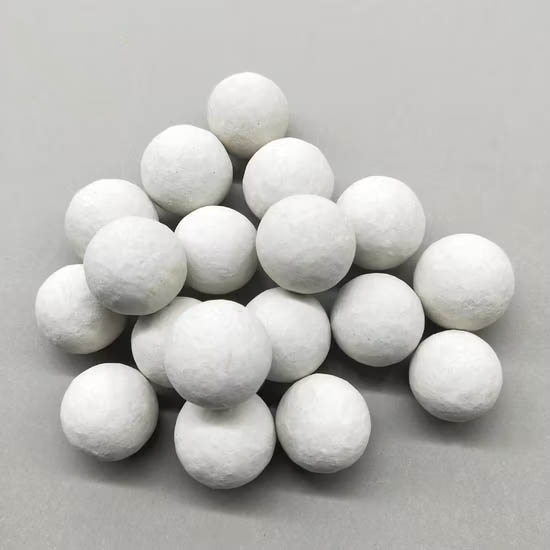

Inert Ceramic Balls 3mm to 50mm

Inert Ceramic Balls are widely used as support and covering materials for catalysts in reactors and packing in towers. They are manufactured from high-quality chemical porcelain clay, providing excellent mechanical strength, thermal resistance, and chemical stability. These ceramic balls offer low water absorption and can withstand high temperatures, high pressure, and corrosion from acids, alkalis, and organic solvents. Due to their reliability and durability, inert ceramic balls are considered the most commonly used catalyst support media in petroleum, chemical, fertilizer, natural gas, and environmental protection industries.

High-quality inert ceramic balls used as catalyst support, grinding media, and filler materials. Learn about ceramic spheres, ceramic grinding media specifications, applications, and advantages.

Inert ceramic balls are widely used in chemical, petrochemical, and refining industries. These balls serve as catalyst bed support and protect active catalysts. Ceramic spheres are known for their high strength and excellent stability. They are resistant to thermal shock, corrosion, and mechanical stress. As a result, inert ceramic balls are a reliable choice for demanding applications.

Features of Inert Ceramic Balls

Inert ceramic balls have smooth surfaces and uniform size. They are chemically stable and do not react with most chemicals. The balls have high compressive strength, making them durable under pressure. Ceramic spheres show low water absorption and excellent resistance to acids. These features extend the service life of catalyst beds and grinding systems.

Specifications

Inert ceramic balls come in a wide range of diameters. Typical sizes include 3mm, 6mm, 13mm, 19mm, and 25mm. The alumina content can vary from 23% to over 99%, depending on the application. Higher alumina ceramic spheres provide better mechanical strength. Customized sizes of ceramic grinding media are also available.

Technical Parameter

| Size (mm) | Alumina Content (%) | Water Absorption (%) | Compressive Strength (N/pc) | Bulk Density (g/cm³) |

|---|---|---|---|---|

| 3 – 6 | 23 – 30 | < 0.5 | > 500 | 1.35 – 1.45 |

| 6 – 13 | 30 – 45 | < 0.5 | > 1000 | 1.40 – 1.50 |

| 13 – 25 | 60 – 75 | < 0.5 | > 3500 | 1.50 – 1.60 |

| 25 – 50 | 75 – 99 | < 0.5 | > 5000 | 1.60 – 1.75 |

Advantages of Ceramic Spheres

Ceramic spheres offer multiple advantages. They distribute gas and liquid evenly in packed towers. They improve mass transfer efficiency in reactors. Inert ceramic balls reduce pressure drop and prevent catalyst loss. They have long service life and lower maintenance costs.

Applications of Ceramic Grinding Media

Ceramic grinding media are widely used in milling processes. They are applied in paint, ink, ceramic, and mineral industries. The balls provide high grinding efficiency with minimal wear. Inert ceramic balls also act as protective layers in catalytic reactors. They are suitable for both wet grinding and dry grinding operations.

Packaging and Delivery

Inert ceramic balls are packed in strong woven bags or steel drums. Standard package sizes include 25kg bags or 1,000kg jumbo bags. Packaging is designed to ensure safe transport and easy storage. Customized packaging is available upon customer request. All ceramic spheres are delivered with quality inspection reports.