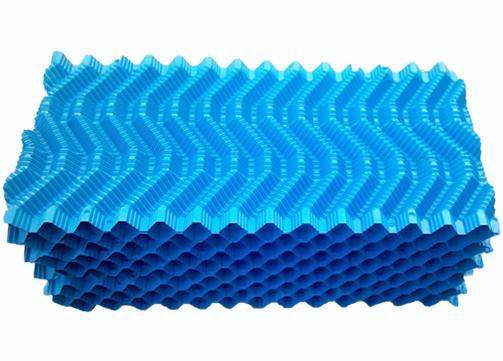

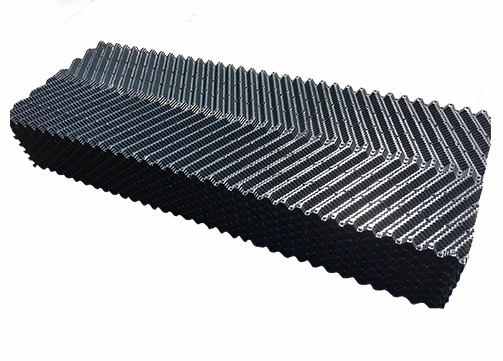

Counterflow Fill

Counterflow fill is an essential cooling tower fill media designed for counterflow cooling towers. It improves heat exchange efficiency by providing a large contact area between water and air, ensuring uniform water distribution and reduced drift loss. Made of durable PVC or PP material, counterflow cooling tower fill offers high thermal performance, low air resistance, and long service life, making it a reliable solution for industrial cooling applications.

Counterflow fill is a specially designed cooling tower media used in counterflow cooling towers to maximize thermal performance and water distribution efficiency. It provides a large contact surface area for air and water, ensuring better heat transfer while reducing water drift and splash loss. With its optimized structure, counterflow fill enhances tower efficiency, conserves water, and lowers operating costs.

Features

- High thermal performance with excellent water distribution

- Durable construction resistant to UV, chemicals, and biological attack

- Lightweight yet strong, easy to install and replace

- Low air resistance, promoting efficient cooling

- Designed to minimize scaling, clogging, and fouling

Specifications

- Material: PVC or PP (polypropylene)

- Sheet thickness: 0.25–0.5 mm (customizable)

- Color: Black, blue, or customizable

- Maximum continuous operating temperature: 55–70°C (depending on material)

- Standard block size: Adjustable according to tower design

Advantages

- Improves cooling tower performance with optimized heat exchange

- Longer service life compared to traditional splash fill

- Energy-efficient due to reduced air resistance

- Compatible with most counterflow cooling tower designs

- Cost-effective with easy maintenance

Applications

Counterflow fill is widely used in:

- Industrial counterflow cooling towers

- HVAC cooling systems

- Power plants and chemical processing facilities

- Metallurgy and steel industries

- Water treatment and refrigeration applications

Packaging

- Packed in bundles with PE straps

- Palletized for safe transportation

- Customized packaging available upon request