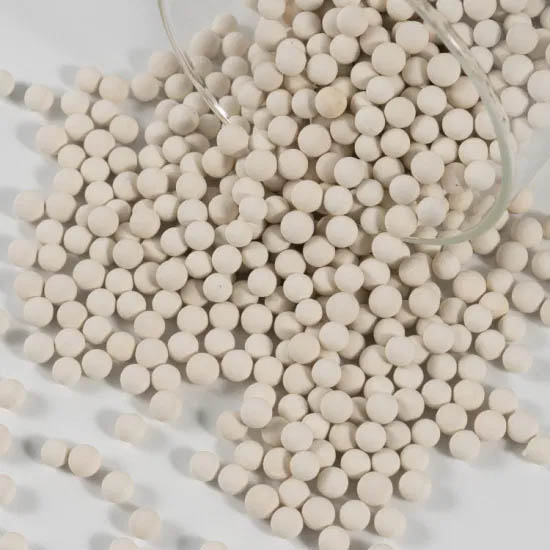

Mid-Alumina Ceramic Balls 3-10mm – Alumina Grinding Media & Inert Porcelain Support Balls

Mid-Alumina Ceramic Ball with 65%-75% Al2O3 offers excellent wear resistance, high mechanical strength, and chemical stability, making it an ideal choice for industrial applications. Widely used as ceramic media balls, alumina grinding media, and alumina spheres, it ensures efficient grinding, long service life, and low maintenance costs. These mid-alumina balls are suitable for cement mills, ceramic production, chemical processing, mining, and petroleum industries. Their smooth surface reduces equipment abrasion while maintaining stable performance under continuous operation, providing a cost-effective solution between low and high alumina grinding media.

Mid-Alumina Ceramic Ball is a high-quality grinding and support media widely used in various industrial applications.

As an efficient type of ceramic media balls, it offers balanced performance between cost and durability.

With an alumina content between 65% and 75%, the Mid-Alumina Ceramic Ball provides better wear resistance and chemical stability compared to low alumina balls, while remaining more economical than high alumina grinding media.

It is also known as alumina grinding media or alumina spheres in many industries.

Mid-Alumina Inert Ceramic Balls are widely used in various industries, including petroleum, chemical engineering, fertilizer production, natural gas, and environmental protection.

As high-quality ceramic media balls and alumina grinding media, they serve as covering and supporting materials for catalysts in reaction vessels and as packing in towers.

These Mid-Alumina Ceramic Balls have stable chemical properties, low water absorption, excellent resistance to high temperatures and high pressure, and strong corrosion resistance against acids, alkalis, and certain organic solvents.

They can withstand temperature fluctuations during industrial processes.

The primary function of inert ceramic balls is to enhance the distribution of gas or liquid, while supporting and protecting low-strength activating catalysts, ensuring efficient operation and prolonged service life.

Feature

- Alumina content: 65%–75%, providing a balance of strength and cost-effectiveness.

- High mechanical strength and good wear resistance.

- Excellent thermal stability and corrosion resistance.

- Smooth surface ensures low abrasion to equipment.

- Available in a wide range of diameters for diverse grinding and support applications.

Specification

| Property | Value |

|---|---|

| Alumina Content (Al2O3) | 65%–75% |

| Bulk Density | 2.2–2.6 g/cm³ |

| Crushing Strength | > 4 KN (for Φ30mm) |

| Water Absorption | < 0.5% |

| Operating Temperature | ≤ 1100°C |

| Available Sizes | Φ3mm–Φ50mm |

Crush Strength

| Size | Crush Strength Kgf/particle | Crush Strength KN/particle |

|---|---|---|

| 1/8″ (3mm) | >40 | >0.4 |

| 1/4″ (6mm) | >80 | >0.8 |

| 3/8″ (10mm) | >190 | >1.90 |

| 1/2″ (13mm) | >580 | >5.8 |

| 3/4″ (19mm) | >900 | >9.0 |

| 1″ (25mm) | >1200 | >12.0 |

| 1-1/2″ (38mm) | >1800 | >18.0 |

| 2″ (50mm) | >2150 | >21.5 |

Size and Tolerance(mm)

| Size | 3/6/9 | 9/13 | 19/25/38 | 50 |

|---|---|---|---|---|

| Tolerance | ±1.0 | ±1.5 | ±2 | ±2.5 |

Advantage

Compared with low-alumina and high-alumina grinding media, Mid-Alumina Ceramic Balls provide a cost-effective solution

for industries requiring both performance and economic efficiency. They deliver higher durability than regular ceramic media

while being more affordable than premium alumina spheres. This makes them an excellent choice for bulk grinding operations.

- Cost-effective alternative to high alumina grinding media.

- Improves grinding efficiency and reduces production costs.

- Long service life and low maintenance requirements.

- Stable performance under continuous operation.

Application

Mid-Alumina Ceramic Balls are widely applied in different industries as ceramic media balls and alumina grinding media.

They serve as both grinding media and catalyst support materials. Common applications include:

- Cement plants – used as grinding media in ball mills.

- Ceramic industry – raw material grinding and mixing.

- Chemical industry – catalyst support and tower packing.

- Mining – ore grinding and mineral processing.

- Petroleum and gas – support media in refining processes.

Package

To ensure safe transportation and storage, Mid-Alumina Ceramic Balls are packed in strong woven bags, ton bags, or steel drums

according to customer requirements. Standard packing includes:

- 25kg woven bag with inner plastic lining.

- 500kg–1000kg jumbo bag for bulk orders.

- Customized packaging available upon request.