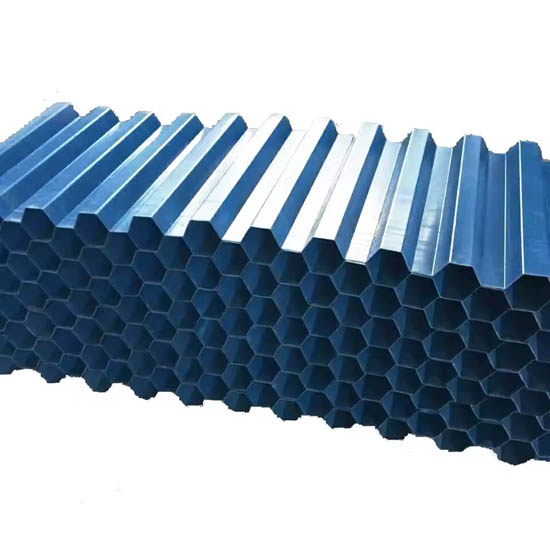

Tube Settler – Lamella Clarifier for Efficient Water Treatment

The Tube Settler is a compact and highly efficient water treatment system designed to improve sedimentation processes. It consists of a series of inclined lamella plates, which increase the settling surface area while reducing the space required for installation. Ideal for applications such as municipal and industrial water treatment, the Tube Settler significantly enhances particle removal, improves water quality, and optimizes space usage. It is made from durable, corrosion-resistant materials like PVC and HDPE, ensuring long-lasting performance in various water treatment environments.

A Tube Settler is a highly effective water treatment device used to improve the sedimentation process in clarifiers. It features a set of inclined lamella plates arranged in a vertical tube structure, promoting the settling of particles more efficiently compared to conventional clarifiers. This system is widely used in water treatment plants for both municipal and industrial applications, significantly improving the quality of treated water.

Feature:

– Lamella Clarifier Design: Tube settlers are composed of a series of inclined lamella plates that maximize the surface area for particle sedimentation.

– Compact and Space-Efficient: The vertical tube structure minimizes the footprint, making it ideal for areas with limited space.

– Improved Sedimentation Efficiency: The design ensures faster settling rates by reducing turbulence and increasing the settling area.

– Corrosion-Resistant Materials: Typically made from high-quality PVC, PP, or HDPE, ensuring durability in harsh environments.

– Modular Structure: Easy to install and scale up as per water treatment requirements.

Specification:

– Material: PVC, PP, HDPE

– Plate Inclination Angle: 60° – 80°

– Plate Width: 100 mm to 400 mm (customizable)

– Plate Length: Varies from 1000 mm to 3000 mm (customizable)

– Settling Capacity: Can handle flow rates from 100 m³/h to several thousand m³/h depending on the design.

– Temperature Resistance: Up to 60°C for PVC, higher for HDPE material.

– Efficiency: Up to 90% improvement in settling efficiency compared to traditional clarifiers.

Advantage:

– High Sedimentation Efficiency: The lamella clarifier’s design allows for enhanced particle settling in a compact space, providing a much higher settling velocity than conventional clarifiers.

– Space-Saving: With the vertical tube structure, tube settlers occupy less space compared to traditional settling tanks, making them ideal for installations in limited areas.

– Cost-Effective: Lower maintenance and operational costs due to the use of durable, corrosion-resistant materials.

– Scalable: Modular units can be combined to meet the required flow capacity, making the system highly flexible.

– Easy Installation: Pre-fabricated modules are easy to install, reducing time and labor costs during the setup process.

Application:

Tube settlers are used in a variety of water treatment applications including:

– Municipal Wastewater Treatment: Enhances the removal of suspended solids from wastewater.

– Industrial Wastewater Treatment: Effective in industries such as paper mills, food processing, and chemical plants.

– Drinking Water Treatment: Improves the clarity of drinking water by efficiently removing particles.

– Mining and Mineral Processing: Used to clarify process water by removing fine solids and suspended particles.

– Aquaculture: Ensures water quality by removing solids in fish farms and aquaculture facilities.

Package:

– Standard Packaging: The tube settler modules are pre-fabricated and packed in a compact and secure manner to ensure safe transportation.

– Customization: Units can be custom-packed based on size and design requirements.

– Shipping: Units are shipped worldwide using reliable freight services. Delivery time depends on location and order volume.