Plastic Pall Ring Packings ( ptfe,pvc,pvdf, polypropylene)

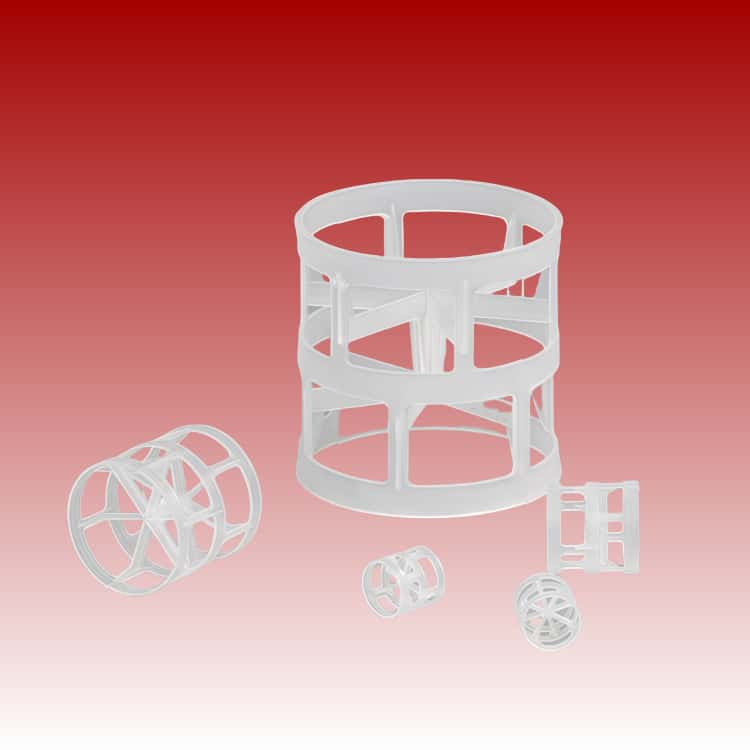

plastic pall ring packings ( ptfe,pvc,pvdf, polypropylene)is a highly efficient form of random packing used in mass transfer applications. Compared to traditional Raschig Rings, the plastic pall ring features a unique design with rectangular openings and inward-facing blades. These structural improvements increase the internal surface area, enhance gas-liquid agitation, and improve the efficiency of gas-liquid…

plastic pall ring packings ( ptfe,pvc,pvdf, polypropylene)is a highly efficient form of random packing used in mass transfer applications. Compared to traditional Raschig Rings, the plastic pall ring features a unique design with rectangular openings and inward-facing blades. These structural improvements increase the internal surface area, enhance gas-liquid agitation, and improve the efficiency of gas-liquid contact. Its design helps achieve high mass transfer rates while maintaining low pressure drop, making it suitable for a variety of chemical processes.

The plastic pall ring structure includes a high void ratio and uniformly distributed openings. These characteristics allow for smooth gas and liquid flow, reducing resistance and promoting efficient mass transfer. Each plastic pall ring has window blades that improve liquid dispersion, reducing the risk of blockages and ensuring even distribution of fluids across the tower’s cross-section.

Plastic pall ring packing is available in several materials including polypropylene pall rings, ptfe pall ring, pvc pall ring, and pvdf pall ring. These materials offer various benefits such as excellent corrosion resistance, lightweight structure, high mechanical strength, and adaptability to different temperature conditions. With a wide selection of diameters and thicknesses, plastic pall rings can be customized for your system’s specific requirements.

Key Features of Plastic Pall Ring Packing

- High void ratio and low pressure drop.

- Uniform gas-liquid contact improves mass transfer efficiency.

- Low height of mass transfer unit, high flooding point.

- Durable design with strong impact resistance.

- Corrosion-resistant materials suitable for aggressive chemical environments.

- Easy to load, unload, and clean.

Material Options and Performance

Plastic pall rings are manufactured from a range of materials. Polypropylene pall rings offer excellent chemical resistance and can withstand temperatures above 100°C. PTFE pall ring is ideal for highly corrosive environments with operation temperatures over 150°C. PVC pall ring is suitable for general chemical applications, while PVDF pall ring combines high strength with superior resistance to aggressive chemicals.

Different plastic pall ring sizes provide various bulk densities and surface areas to match the needs of different tower designs. The structural variations between sizes help ensure that the packing provides optimal contact between gas and liquid phases.

Technical Parameters

| Item | Size (D × T × H mm) | Bulk Density (kg/m³) | Filling Quantity | Surface Area (m²/m³) | Voidage (%) |

|---|---|---|---|---|---|

| PRPT-01 | 16 × 1 × 16 | 141 | 230000 | 260 | 91 |

| PRPT-02 | 25 × 1.2 × 25 | 85 | 48300 | 213 | 91 |

| PRPT-03 | 38 × 1.4 × 38 | 82 | 15800 | 151 | 91 |

| PRPT-04 | 50 × 1.5 × 50 | 60 | 6300 | 100 | 92 |

| PRPT-05 | 76 × 2.6 × 76 | 62 | 1930 | 72 | 92 |

Note:

Material: PE, PP, RPP, PVC, CPVC, PVDF

Diameter: 16 mm, 25 mm, 38 mm, 50 mm, 76 mm.

Thickness: 1 mm, 1.2 mm, 1.4 mm, 1.5 mm, 2.6 mm.

Advantages of Plastic Pall Ring

- Special structure ensures high flow rate with minimal pressure drop.

- Strong resistance to chemical corrosion across various industrial environments.

- Large surface area for effective mass transfer processes.

- Lightweight and energy-saving design reduces operating costs.

- Easy to install and remove from packed towers.

Applications

Plastic pall ring packing is widely used in absorption, scrubbing, stripping, and distillation towers. It is a preferred choice in industries such as chemical processing, gas treatment, petroleum refining, chlor-alkali production, and environmental engineering. Its durability and adaptability make it ideal for both high and low-load operations.

Whether you’re seeking a reliable polypropylene pall ring for general chemical applications, a ptfe pall ring for aggressive corrosive systems, or a high-performance pvdf pall ring for extreme conditions, plastic pall ring packings offer a flexible and efficient solution for your process needs. As one of the most widely used pall ring packing types, it provides optimal performance across many gas-liquid separation processes.