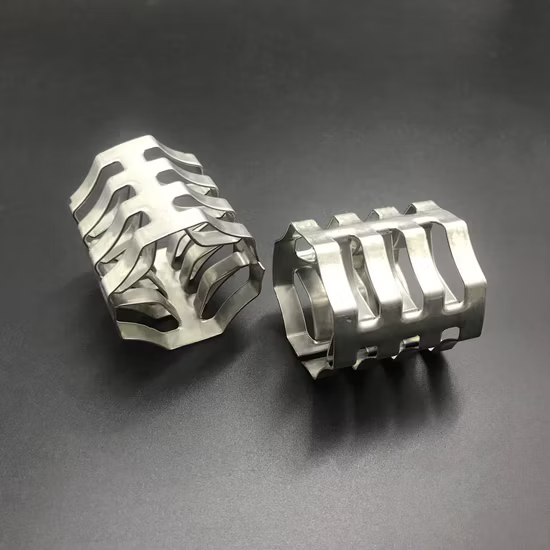

Ss304 Metal VSP Ring(25mm 38mm 50mm 76mm)

Metal VSP Ring is a high-efficiency random packing designed with vertical spiral partitions for improved mass transfer, low pressure drop, and large capacity. Made from stainless steel, carbon steel, or aluminum alloy, it offers excellent corrosion resistance and durability. Widely used in distillation, absorption, and stripping processes, Metal VSP Ring is ideal for petrochemical, fertilizer, pharmaceutical, and environmental industries.

Metal VSP Ring (Vertical Spiral Partition Ring), also known globally as Mella Ring, is a high-efficiency random packing widely used in chemical and petrochemical industries. It is designed with a unique spiral structure that provides uniform geometric symmetry, high voidage, and excellent liquid distribution. Compared with traditional metal Pall Ring, Metal VSP Ring offers 15–30% higher liquid and gas throughput, while reducing pressure drop by 20–30%.

Made from high-quality stainless steel, carbon steel, or aluminum alloy, Metal VSP Ring has thin walls, strong mechanical strength, high heat resistance, and superior corrosion resistance. This special packing is particularly effective for processes that require high capacity, low resistance, and excellent separation efficiency.

Features of Metal VSP Ring

- Available materials: carbon steel, SS304, SS304L, SS316, SS316L, SS410, aluminum alloy.

- High crushing strength and easy installation.

- Excellent temperature resistance for harsh working conditions.

- High flooding point and low wetting point for efficient operation.

- Large free volume and high separation efficiency.

These features make Metal VSP Ring ideal for both standard and demanding chemical applications.

Specification & Technical Performance

The structure of Metal VSP Ring consists of evenly folded inner arcs arranged alternately along the axial direction. This unique geometry increases the contact area between liquid and gas, ensuring better mass transfer efficiency.

Product Parameters

| Specification (mm) | Size (mm) | Bulk numbers (per/m³) | Surface area (m²/m³) | Bulk density (kg/m³) | Free volume (%) | Dry packing Factor (m⁻¹) |

|---|---|---|---|---|---|---|

| Φ25 | 25×25×0.6 | 59,200 | 250 | 420 | 93 | 310 |

| Φ38 | 38×38×0.6 | 14,500 | 138 | 350 | 94.7 | 163 |

| Φ50 | 50×50×0.8 | 7,000 | 121 | 300 | 95 | 144 |

| Φ76 | 76×76×1.0 | 1,950 | 75 | 280 | 95 | 86 |

This data shows that Metal VSP Ring provides high surface area, low bulk density, and excellent free volume, which ensures efficient mass transfer and reduced pressure drop.

Advantages of Metal VSP Ring

- Thin wall and lightweight design.

- Large free volume and high capacity.

- Low resistance, reducing energy consumption.

- Self-cleaning characteristics, preventing fouling and blockage.

- Excellent heat resistance, suitable for vacuum distillation of heat-sensitive materials.

- Long service life due to corrosion-resistant materials.

By using Metal VSP Ring, users benefit from stable performance, higher productivity, and reduced operational costs.

Applications of Metal VSP Ring

- Petrochemical industry distillation and absorption processes.

- Refinery gas processing and hydrocarbon separation.

- Environmental protection and emission reduction systems.

- Fertilizer production and fine chemical processing.

- Pharmaceutical industry for high-purity separation.

- New energy and advanced material industries.

Its versatility makes Metal VSP Ring a preferred choice for improving efficiency in packed towers, absorption columns, and stripping units.

Packaging & Supply

Metal VSP Ring is carefully packaged to prevent damage during transportation. It can be supplied in woven bags, cartons, or wooden boxes, depending on order quantity and customer requirements. Bulk packaging and customized packing solutions are also available.