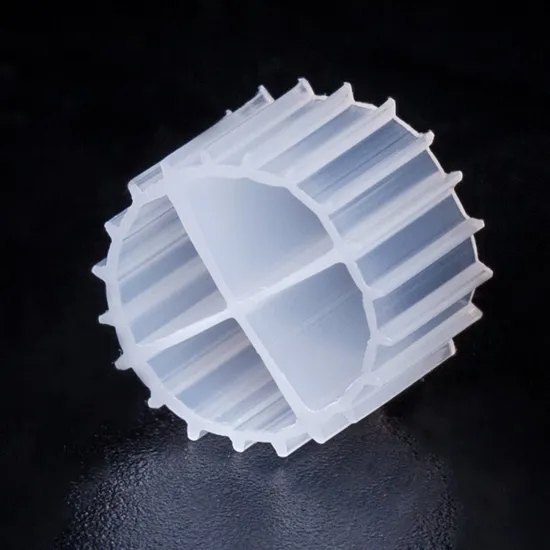

K1 K3 PE05 PE08 HDPE MBBR Bio Filter Media for Wastewater and Aquaculture Treatment

K1 K3 PE05 PE08 MBBR Bio Filter Media are high-performance HDPE biofilm carriers designed for Moving Bed Biofilm Reactor (MBBR) systems. These media provide a large protected surface area for microbial growth, improving the biological degradation of BOD, COD, and ammonia in wastewater and aquaculture applications. Made from durable, non-toxic HDPE, the MBBR carriers feature excellent impact resistance, self-cleaning ability, and long service life. Ideal for municipal, industrial, and fish pond water treatment systems.

MBBR Media is an advanced biofilm carrier designed for Moving Bed Biofilm Reactor (MBBR) systems used in modern wastewater treatment processes.

It provides a large and stable surface area for microorganism attachment, enhancing the biological degradation of organic matter, ammonia, and nutrients in both industrial and municipal water systems.

Within the MBBR reactor, these MBBR carriers freely move and mix with wastewater, maintaining optimal contact between biofilm, oxygen, and nutrients, resulting in highly efficient treatment performance.

MBBR Media is widely applied in MBBR water treatment systems for municipal, industrial, and aquaculture applications.

Feature

- High Specific Surface Area: Special internal structure design provides maximum surface area for biofilm growth, improving biological treatment efficiency.

- Lightweight and Floating: With a density around 0.96 g/cm³, the media remain suspended in water and resist sedimentation or clogging.

- Self-Cleaning and Non-Clogging: Continuous movement and surface shear prevent excessive biofilm accumulation, ensuring stable reactor operation.

- Durable and Non-Toxic Material: Manufactured from 100% virgin HDPE (High-Density Polyethylene), resistant to chemicals, aging, and UV exposure.

- Flexible to Load Variations: MBBR reactors automatically adapt to fluctuating inflow loads without operational adjustments.

- Low Energy and Space Saving: Compact reactor design reduces footprint and energy use compared to traditional activated sludge systems.

Specification

| Item | Typical Value | Description |

|---|---|---|

| Material | 100% Virgin HDPE | Non-toxic, high durability polymer |

| Density | ≈ 0.96 g/cm³ | Floating in water, easy fluidization |

| Bulk Density | ≈ 100 kg/m³ | When packed or stored in bulk |

| Shape / Size | Typical 25 × 10 mm (customizable) | K1, K3, K5 types available |

| Filling Ratio | 25–65% (v/v) | Recommended loading in MBBR reactor |

| Effective Surface Area | 500–1200 m²/m³ | Depending on model and design |

| Service Life | > 15 years | Wear-resistant and UV-stable |

| Color | White / Black / Customized | Optional for branding or system matching |

Advantage

- Rapid Biofilm Formation: Special surface texture promotes fast microbial growth and system startup.

- No Sludge Return Required: Simplified process without the need for activated sludge recirculation.

- Shock Load Resistant: Maintains stable operation during fluctuations in water quality and organic load.

- Compact & Energy Efficient: Smaller footprint and lower aeration energy than conventional biological systems.

- High Treatment Efficiency: Effectively removes BOD, COD, ammonia, total nitrogen (TN), and phosphorus (TP).

- Environmentally Friendly: Non-toxic material without plasticizers or heavy metals; safe for aquatic life.

- Easy Retrofit Capability: Ideal for upgrading existing wastewater plants by adding MBBR carriers into existing tanks.

Application

MBBR Media is suitable for a wide range of moving bed bio reactor MBBR and MBBR water treatment systems, including:

- Municipal sewage treatment plants for BOD, COD, and nutrient removal.

- Industrial wastewater treatment — food & beverage, chemical, pulp & paper, textile, and pharmaceutical sectors.

- Decentralized and modular wastewater treatment units.

- Aquaculture and koi pond filtration systems (e.g., K1 Micro Kaldnes Filter for Koi Pond).

- River and lake remediation, ecological restoration, and polishing units.

- Ammonia and nitrogen removal, nitrification, and denitrification processes.

Package

- Standard Package: 0.1 m³ per woven bag, convenient for handling and installation.

- Bulk Package: 1 m³ jumbo bag for large-scale MBBR reactor projects.

- Transportation: Keep dry, avoid direct sunlight and heavy compression during transport and storage.

- Lead Time: Normally within several working days depending on order quantity and model type.

- Quality Inspection: Each batch is tested for size, density, floating ability, and surface integrity before delivery.