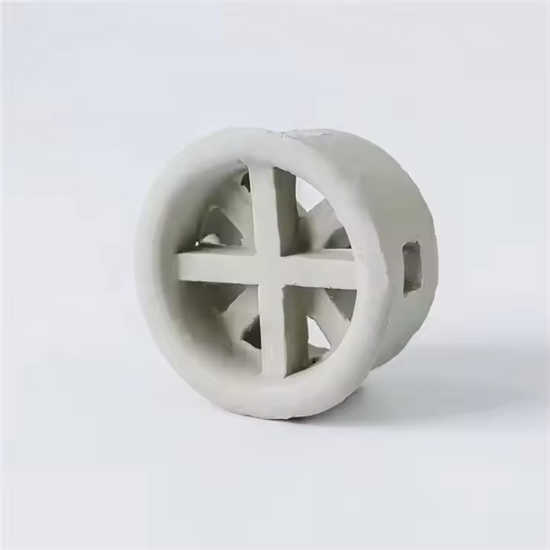

Ceramic Cascade Mini Ring 25mm 50mm 76mm

the Ceramic Cascade Mini Ring is an indispensable tool for industries looking to optimize mass transfer, improve plant capacity, and reduce pressure drops. With its acid and alkali resistance, heat resistance, and superior mechanical strength, it is ideal for a variety of demanding industrial applications. Whether you’re involved in metallurgy, chemicals, pharmaceuticals, or any other industry requiring high-performance packing materials, the ceramic cascade mini ring is the perfect solution for improving efficiency and reliability in your operations.

Ceramic Cascade Mini Ring is a highly efficient random packing material that has evolved from the Pall Ring and Raschig Ring, specially designed to reduce pressure drop and enhance plant capacity. With its unique structure, the ceramic cascade mini ring offers numerous advantages in various industrial applications. This product is known for its enhanced mechanical strength, improved vapor-liquid distribution, and significant improvements in mass transfer efficiency, making it a go-to choice in chemical and industrial processing.

Key Features of Ceramic Cascade Mini Ring

- Acid and alkali resistance for durability in harsh conditions.

- Excellent heat resistance, allowing for use in high or low-temperature environments.

- High specific surface area, which contributes to improved mass transfer.

- Low cost with multiple size options to meet different application needs.

- High mechanical strength, which enhances its durability and longevity in industrial settings.

- Low aspect ratio that aids in efficient vapor-liquid contact.

Specifications

The Ceramic Cascade Mini Ring comes in multiple sizes and technical specifications, each designed to optimize performance in various applications. Below is a table that provides details on the sizes, surface area, void fraction, bulk density, and other key parameters:

| Type | Size (mm) |

Specific Surface (m2/m3) |

Void (%) |

Bulk Density (kg/m3) |

Number (N/m3) |

Dry Packing Factor (m-1) |

|---|---|---|---|---|---|---|

| φ25 | 25*17.5*3 | 250 | 69 | 624 | 74000 | 245 |

| φ30 | 30*21*3 | 230 | 72 | 650 | 46200 | 225 |

| φ40 | 40*28*4 | 185 | 81 | 650 | 32500 | 126 |

| φ50 | 50*30*5 | 149.6 | 78 | 580 | 8980 | 120 |

| φ76 | 76*46*9 | 75 | 78 | 530 | 2500 | 158 |

Advantages of Ceramic Cascade Mini Ring

The Ceramic Cascade Mini Ring stands out because of its remarkable acid and heat resistance properties. It can withstand the corrosion of various inorganic acids, organic acids, and organic solvents, excluding hydrofluoric acid. Furthermore, it can be used under both high and low temperatures, making it suitable for a broad range of applications. Its unique design allows for improved vapor-liquid interaction, which is a key factor in its mass transfer efficiency. By increasing the interface between vapor and liquid, it helps to improve the overall effectiveness of industrial processes, including drying, absorption, and cooling operations.

Applications of Ceramic Cascade Mini Ring

The Ceramic Cascade Mini Ring is versatile and widely used in many industries. Due to its low height, thin wall thickness, and low pressure drop, it is particularly beneficial for use in drying and absorbing columns. It is also used extensively in cooling towers, scrubbers, and towers used for acid recovery, desulfurization, and various other industrial processes. Some of the key industries that utilize ceramic cascade mini rings include:

- Metallurgy

- Chemicals

- Fertilizer production

- Pharmaceutical industry

- Gas and oxygen production

- Sulfuric acid production

- Cooling and recovery towers

Packaging

The Ceramic Cascade Mini Ring is packaged carefully to ensure that it arrives in optimal condition for immediate use in industrial applications. Each unit is professionally packed and protected to minimize the risk of damage during shipping. We offer a variety of packaging options to accommodate different order sizes, ensuring safe and secure delivery to your facility.